Shredders

With more than 150 shredders installed worldwide, Danieli Centro Recycling is one of the leaders in the metal recycling industry. Through a continuous process of product development, our shredder plants combine technical innovation with engineering excellence. We deliver scrap shredders from 800 to 10,000 hp that offer world leading performance and reliability at industry leading low operating costs.

With a unique mill geometry and disruptive automation solutions, our shredders can achieve a high throughput with low power consumption. Inside the mill, a complete material disintegration ensures optimum separation and nonferrous product yield. State of the art dust extraction, suppression and control techniques mean that all our equipment meets current and foreseeable statutory environmental requirements.

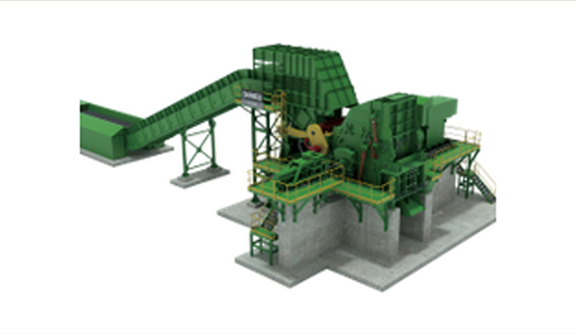

Shredder plants – DCR range

We deliver turnkey scrap shredders plants starting from 600 kW (800 Hp) right up to 7,475 kW (10,000 Hp) that offer world leading performance and reliability at industry leading low operating costs.

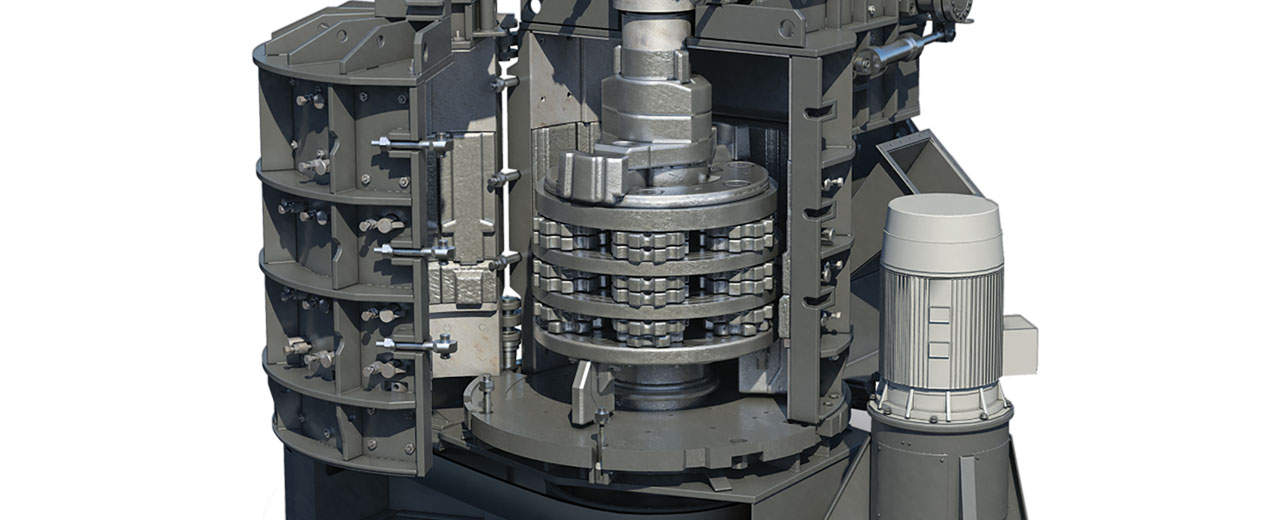

Vertical grinder mills – BMH range

With their very high torque, BMH grinder mills, equipped with a vertical rotor mounted with stars, are especially suitable for processing by the hardening of bulk metallic waste such as new offcuts, blinding, aluminium and armatures, etc

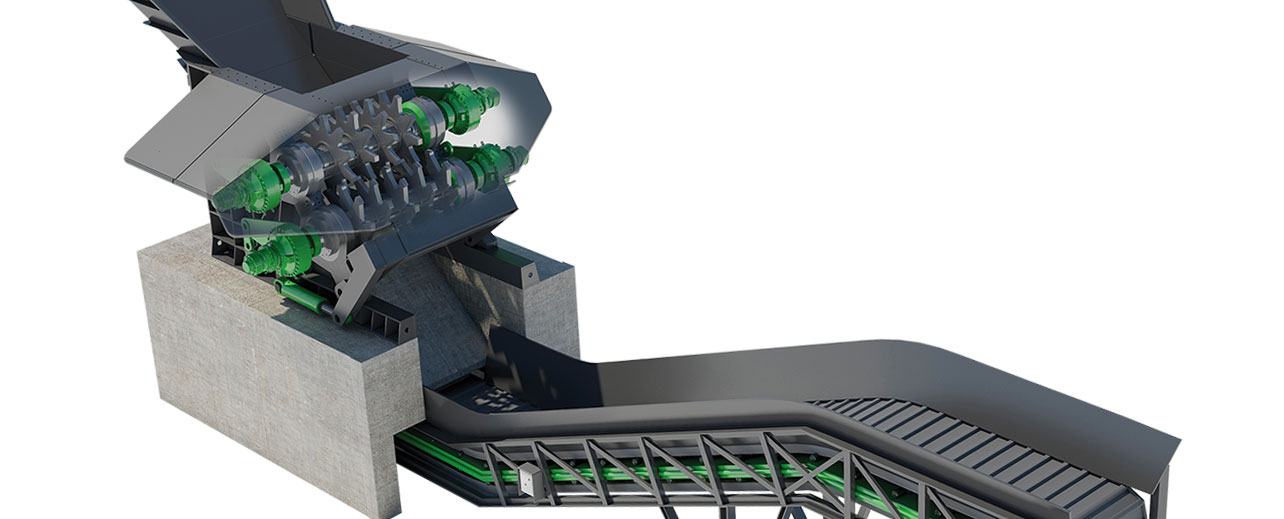

Two- or three-shaft pre-shredders – ZDS / ZTS ranges

ZDS and ZTS pre-shredders are particularly suitable for processing up to 105 t/h of high quality scrap metal such as ELVs, sheet metal, WEEE, etc. in bulk or baled form thanks to their first-rate tooth profile and very high torque.