Baling Presses

As we understand the demands from a foundry, and the bale quality is an important aspect to guarantee the best performance of the furnace, Danieli Centro Recycling had developed baling presses to reduce metal scrap in bales with high density and short working cycle times. The quality of the bales obtained optimizes the recycling of recovered metal material. Transport costs are considerably reduced and storage and handling are facilitated.

Danieli Centro Recycling presses are designed to be operated under the most demanding conditions and suit the needs of recycling companies as well as the needs of industry. Their robust mechanical structure, their latest-generation hydraulic power packs and their automatic operation provide a superior reliability, production output and working life the business requires.

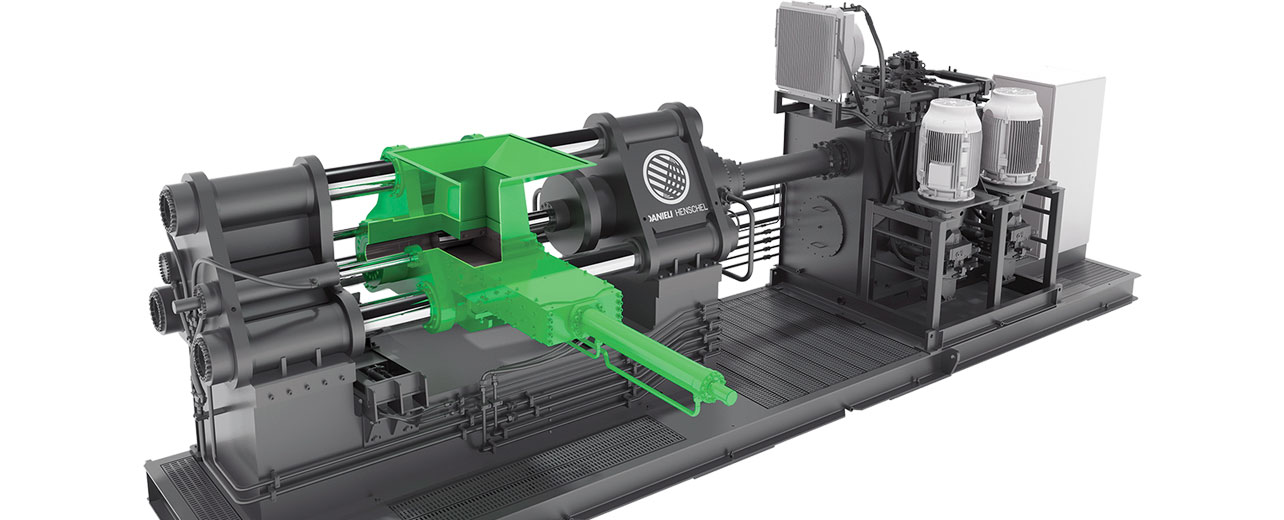

Briquetting balers – PBC range

With output ranging from 0.6 to 8 tonnes per hour, there is a machine available to meet all customer requirements.

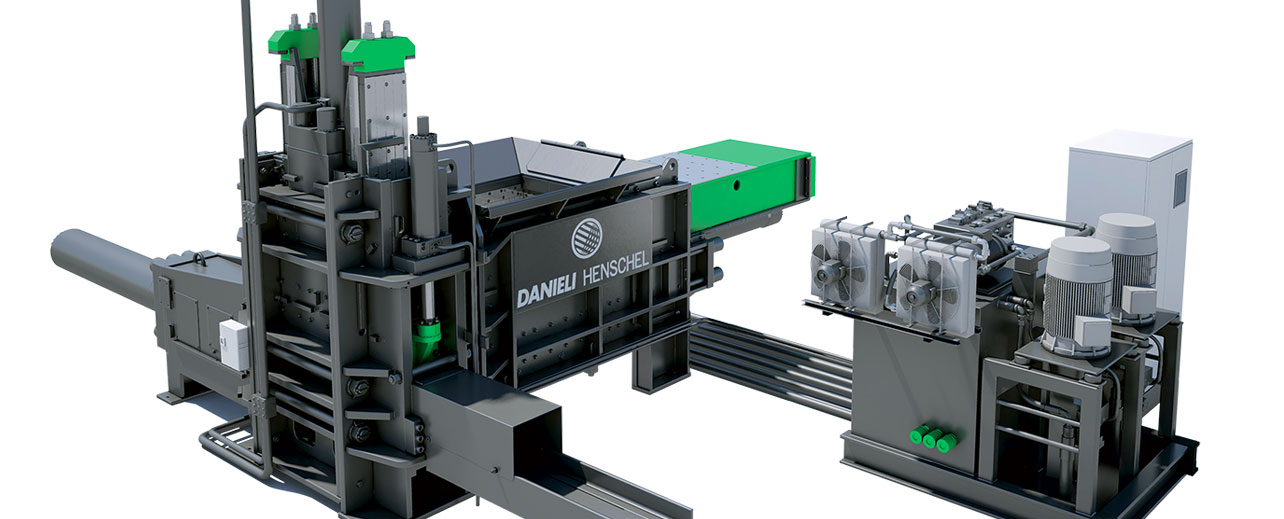

Triple acting balers – PTC range

With the large number of different models available offering output of 10 t/h to 50 t/h, there is a suitable baler to meet every customer’s individual requirements.

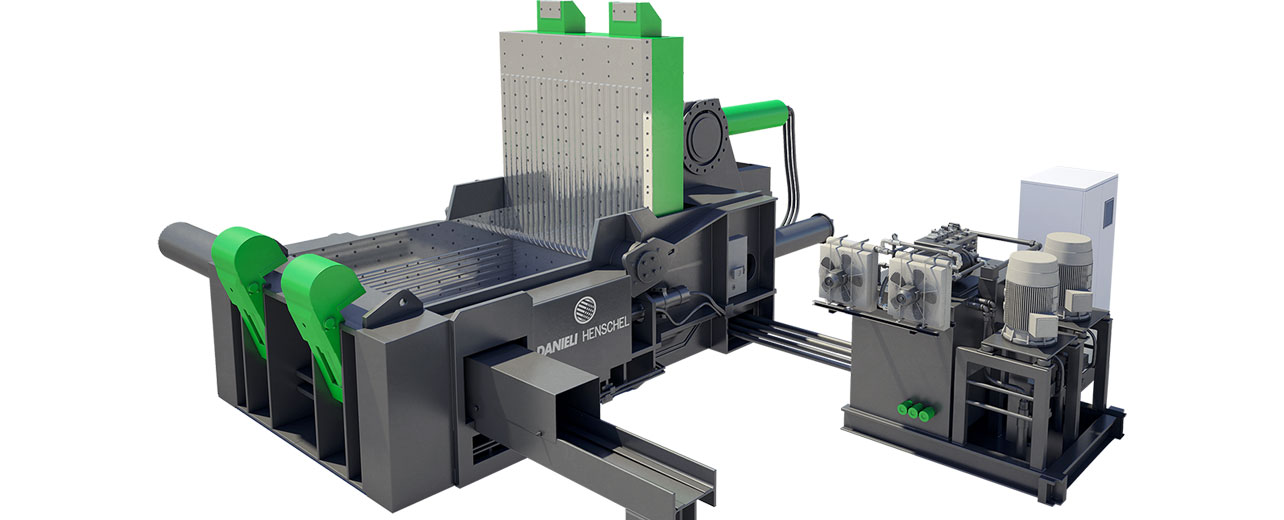

Lid balers – PCV range

Capable to process up to 30 t/h for steel scrap, PCV lid balers offer more flexibility to recycling industries for the compacting of bulky products.

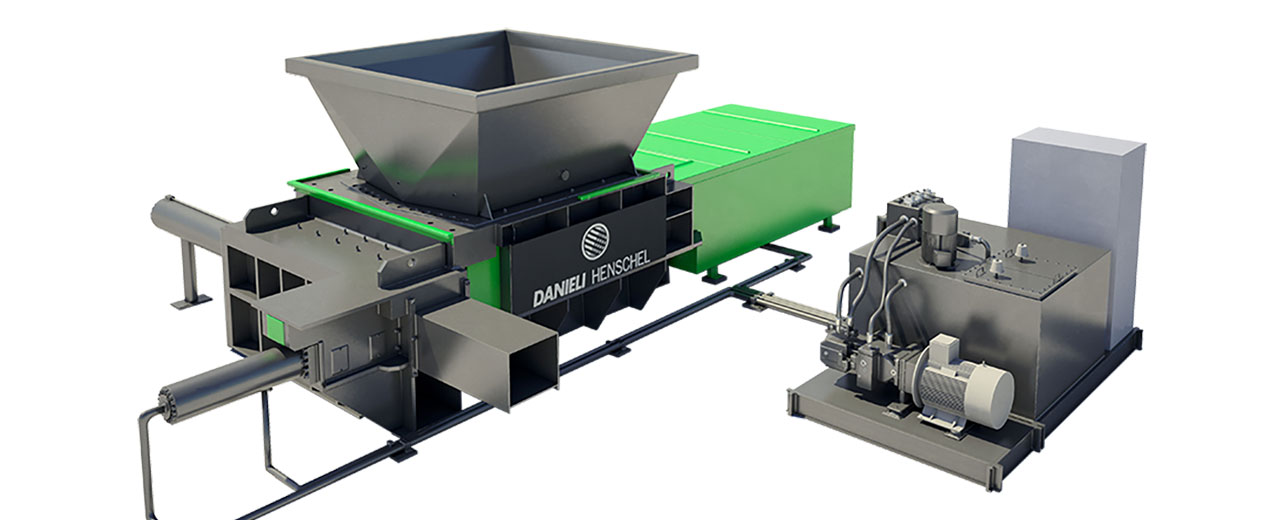

Single- or double-acting baling presses – PSC / PDC ranges

Double-acting automatic baling presses can equally be operated in medium-sized to large scrap yards to process offcuts, aluminium profiles, copper, stainless steel, etc. and in round-the-clock industrial operations to compact manufacturing offcuts.