Scrap shears

Over the last 40 years or more, Danieli Centro Recycling hydraulic scrap shears have acquired a worldwide reputation in the field of metal collection and recycling. Today, four major lines of hydraulic scrap shears allow scrap metal processors to cope with every type of requirement.

– Compact Shear – CIV (Press-Wing Shear) – CIC (Inclined Shear) – CIB (Side Pre-Compression Shear) these scrap shears are designed to cut scrap metal using a guillotine system powered by hydraulic energy.

Because of the different reducer kinematics in each range, our machines can process heavy, bulky scrap metal just as easily as lightweight scrap metal. They also increase the density of the scrap metal collected, while greatly reducing its size. This enables them to process dozens of tons per hour whatever the operating mode: automatic or manual.

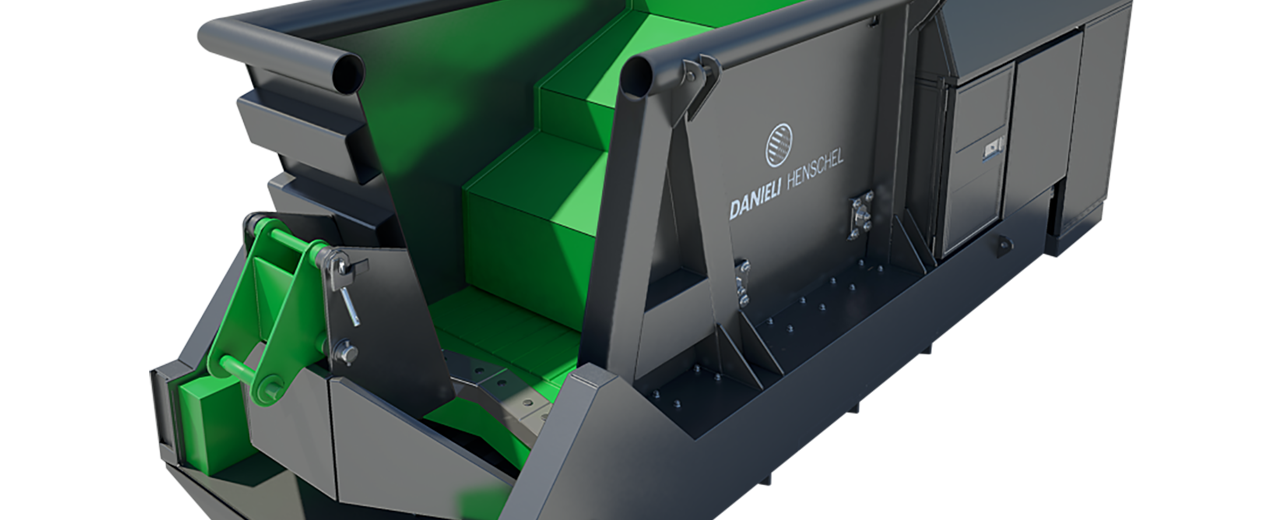

One-piece shear-balers – XPERT range

Easily transported and installed, one-piece wing shears from the XPERT range can shear up to 16 t/h. High densification and accurate cut length guarantee a high-quality finished product.

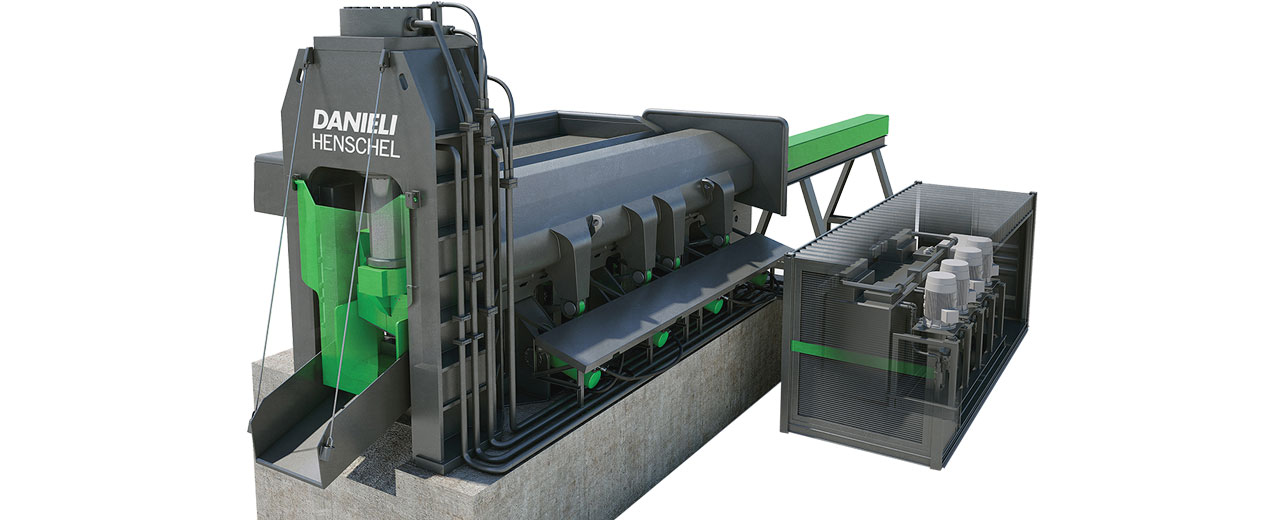

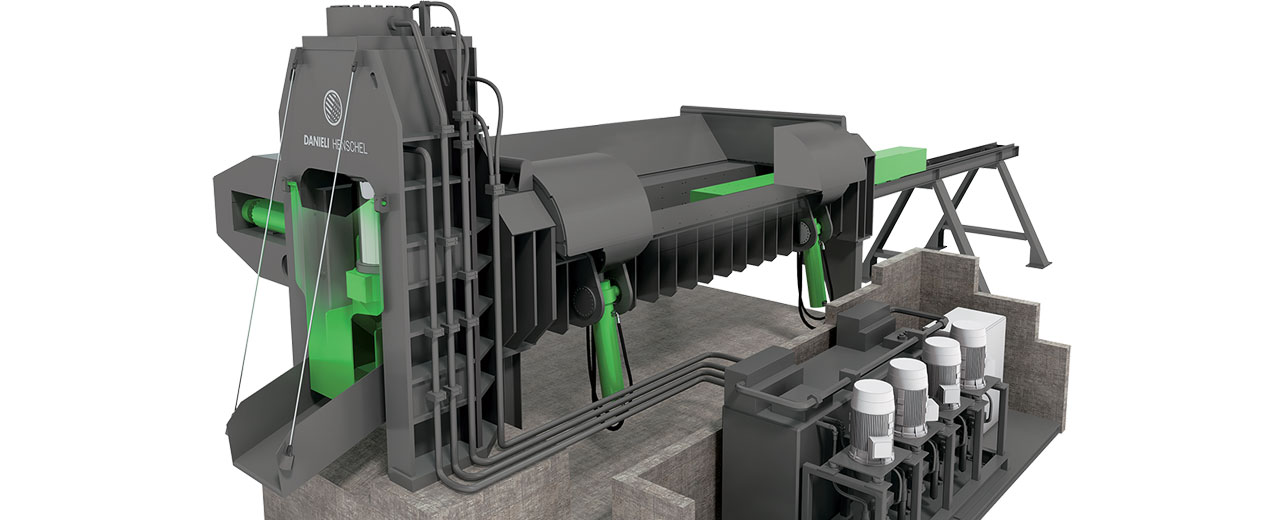

Press-wings scrap shears – CIV range

Specifically designed to be versatile for the processing of more or less lightweight scrap metal, the CIV line of shear-balers can shear up to 50 t/h. High densification and accurate cut length guarantee a high-quality finished product.

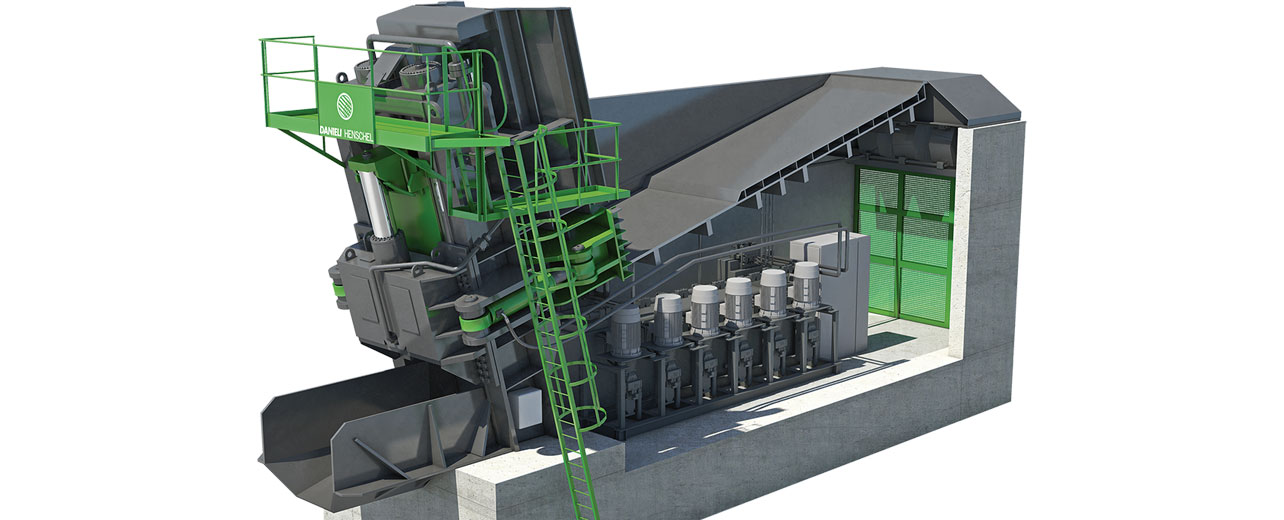

Side compression shear balers – CIB range

Specifically designed for heavy-duty processing of heavy and bulky scrap metal, the CIB line of shear-balers can shear up to 98 t/h. High densification and accurate cut length guarantee a high-quality finished product.

Automatic inclined shears – CIC range

Thanks to their countinuous and fully automatic functionning, inclined shears from the CIC range is particularly suited to treat scrap of great length, requiring high densification and production capacity.