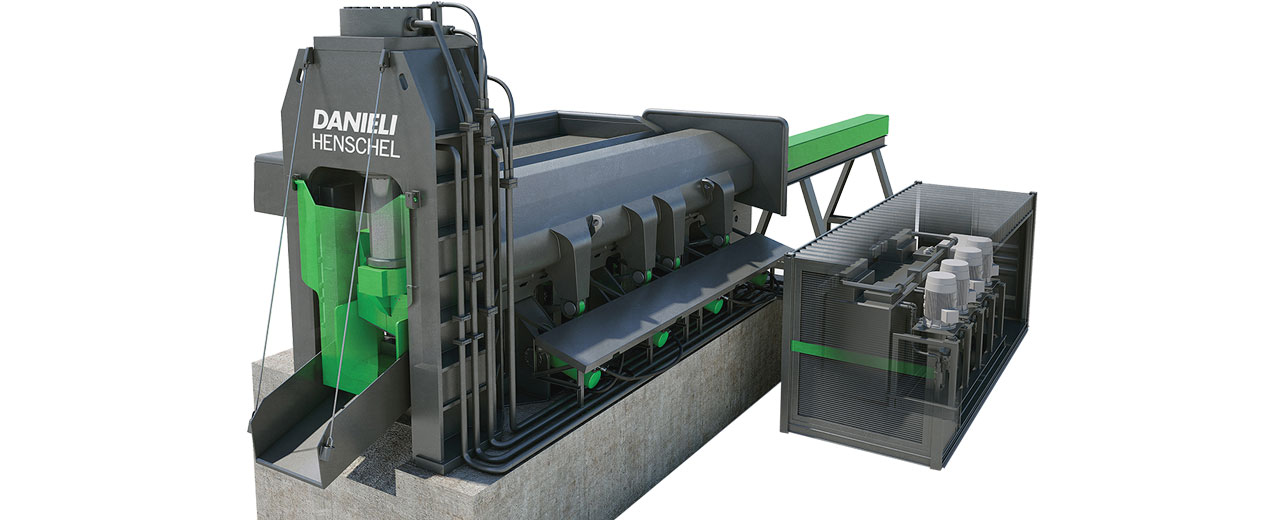

Press-wings scrap shears – CIV range

Versatility and flexibility are the hallmarks of the CIV range!

Scrap shears with press wings are designed to give the customer full control over their operation – either reducing your scrap metal to obtain a bale, or shearing it. The range is designed to suit every size of operation, from a one-piece portable shear complying with EEC road regulations to fixed, heavy shears.

With such versatility, in a single day you can process ELVs (end-of-life vehicles) to make bales, the ideal shape for transporting waste, and also shear metal profiles into short sections to go directly into an electric arc furnace (EAF).

Versatility for shearing and baling.

Heavy weight series for intensive use.

Stationary or easy-to-move machinery.

Built-in or containerisable drive units.

Man/machine dialogue.

Optimized precompression.

Heavy weight series for intensive use.

Stationary or easy-to-move machinery.

Built-in or containerisable drive units.

Man/machine dialogue.

Optimized precompression.

Automatic shearing and baling.

Direct loading or with skip.

Precompression with over stroke on both wings, with automatic or manual control.

Indexing of the shearing and reducing rams by way of magnetostrictive sensors.

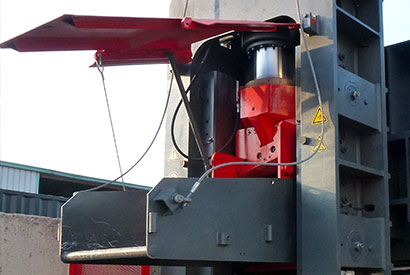

Laser positioning of the ram.

Direct loading or with skip.

Precompression with over stroke on both wings, with automatic or manual control.

Indexing of the shearing and reducing rams by way of magnetostrictive sensors.

Laser positioning of the ram.

The CIV Range of press-wing scrap shears have the following characteristics:

– Shearing force of 1250 t

– Cutting width of 1000 mm

– Pusher force of 180 t

– Installed power of 550kW

– Output of up to 52 tph of sheared scrap and up to 42 tph of baled scrap

– Shearing force of 1250 t

– Cutting width of 1000 mm

– Pusher force of 180 t

– Installed power of 550kW

– Output of up to 52 tph of sheared scrap and up to 42 tph of baled scrap

Ergonomics

- Easy installation, made to suit customer requirements

- Machine feedback via bidirectional remote control

- Human/machine interface via touch screen

- Automatic shearing cycle to suit your requirements

Working life

- Over strokes on outer and inner wings

- Generously sized guide surfaces

- Anti-abrasion wear plates

Maintenance

- Improved accessibility

- Optimized blade replacement phase

- Simple shearing ram adjustment by excentrics from outside the shear

- Grouped weekly greasing points

- GSM modem or telephone line for telediagnosis

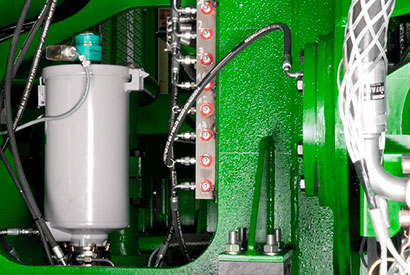

Hydraulic power unit

- Electric or diesel scrap shears versions compliant with latest

- European directives

- Built-in or containerisable hydraulic unit

- Industrial hydraulic pumps

Safety

- Compliant with Machinery Directive 2006/42/EC

- Safety setting in maintenance areas

- Hydraulic hose whiplash protection

Available equipment

- Additional compression by cupola

- Loading skip

- Hydraulic blade holding

- Automatic greasing of shear head and box

- Control cab

- Swiveling steel plate conveyor

Applications