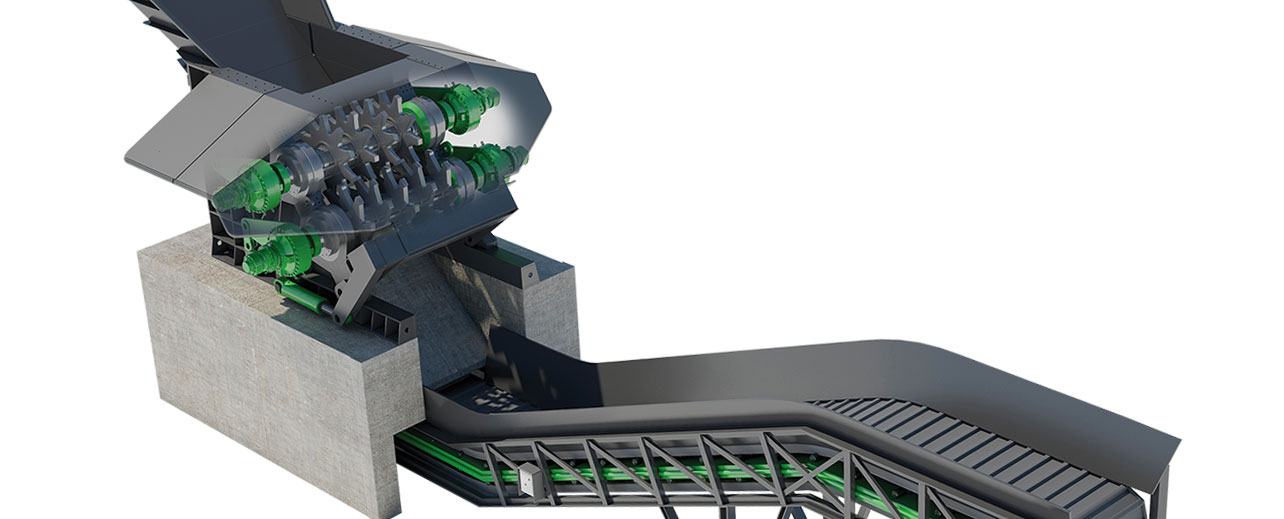

Two- or three-shafts pre-shredders – ZDS & ZTS ranges

Pre-shredders are generally installed upstream from a shredding system to prepare the material for entry into the shredder. Adding a pre-shredder to the metals process allows the operator to control the feed rate, leading to a more uniform flow of material through the shredder itself, and a higher density product. With their first-rate tooth profile and very high torque, Danieli Centro Recycling pre-shredders are truly essential for processing waste metal such as end-of-life vehicles, domestic waste, WEEE, etc. in bulk or baled form.

Supplied with an output of 25 to 120 tons per hour (according to the model and products to be processed), pre-shredders are used to control the grading and quality of products prior to feeding into a shredder.

Improved shredder production by preparing a homogeneously graded, densified product, reducing shredding time.

Significant reduction of explosions in the shredder.

Detection of unshreddable material upstream from the shredder.

Increased service life of wear parts in the shredder.

Smoothing of shredder electricity consumption.

Optimized logistics for collecting products to be processed, by reducing intermediate handling and transport volumes.

Significant reduction of explosions in the shredder.

Detection of unshreddable material upstream from the shredder.

Increased service life of wear parts in the shredder.

Smoothing of shredder electricity consumption.

Optimized logistics for collecting products to be processed, by reducing intermediate handling and transport volumes.

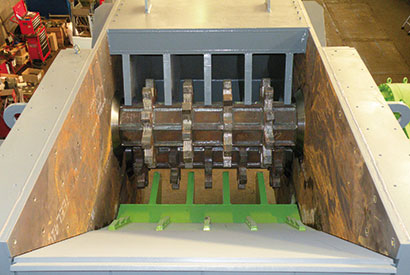

Easier material gripping via articulated ram or third shaft.

Separate adjustable shaft rotation speeds.

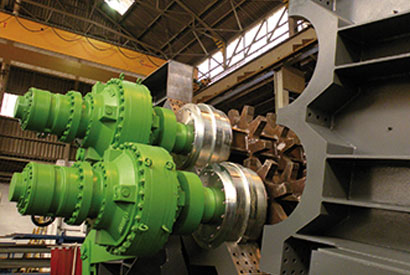

Very high shredding torque.

Shafts equipped with abrasion-proof steel profiled toothing, with ends reloaded with high-carbon steel.

Automatic rejection of unshreddable material by inverting the feed direction.

Independent shaft drive system (2-shaft version).

ZDS range > high production

ZTS range > fine grade

Separate adjustable shaft rotation speeds.

Very high shredding torque.

Shafts equipped with abrasion-proof steel profiled toothing, with ends reloaded with high-carbon steel.

Automatic rejection of unshreddable material by inverting the feed direction.

Independent shaft drive system (2-shaft version).

ZDS range > high production

ZTS range > fine grade

The ZDS and ZTS Ranges of Pre-shredders have the following characteristics:

– 2 or 3 shafts

– Working width of 2200-2500 mm

– Installed power of 840kW

– 2 or 3 shafts

– Working width of 2200-2500 mm

– Installed power of 840kW

Ergonomics

- Easy installation in line with customer requirements

- Machine feedback on the two-way remote control

- Human/machine interface via touch-screen display

Working life

- Body protected by abrasion-proof panels

- Reinforced hydraulic shaft drive system protection

Maintenance

- Easier shaft access via hydraulic opening of upper housing (2-shaft version)

- Lifetime lubricated shaft bearings

- Most maintenance reduced to reloading tooth ends

- Low-Cost Maintenance specific DANIELI hydraulics

- GSM telediagnosis modem

Productivity

- Hopper designed for optimal feed

- Specific equipment increasing material gripping efficiency by teeth

- Tooth profile suitable for all types of products

- Adjusted differential speeds between shafts to optimise material shredding

Safety

- In compliance with the machine directive 2006/42/EC

- Hopper pre-fitted to receive a fire fighting system

- Protection preventing any dangerous oscillation of hydraulic hoses

Available equipment

- Automated heavy swivelling conveyor at pre-shredder outlet

- Metal support frame

- Integral metal covers on concrete walls

Applications