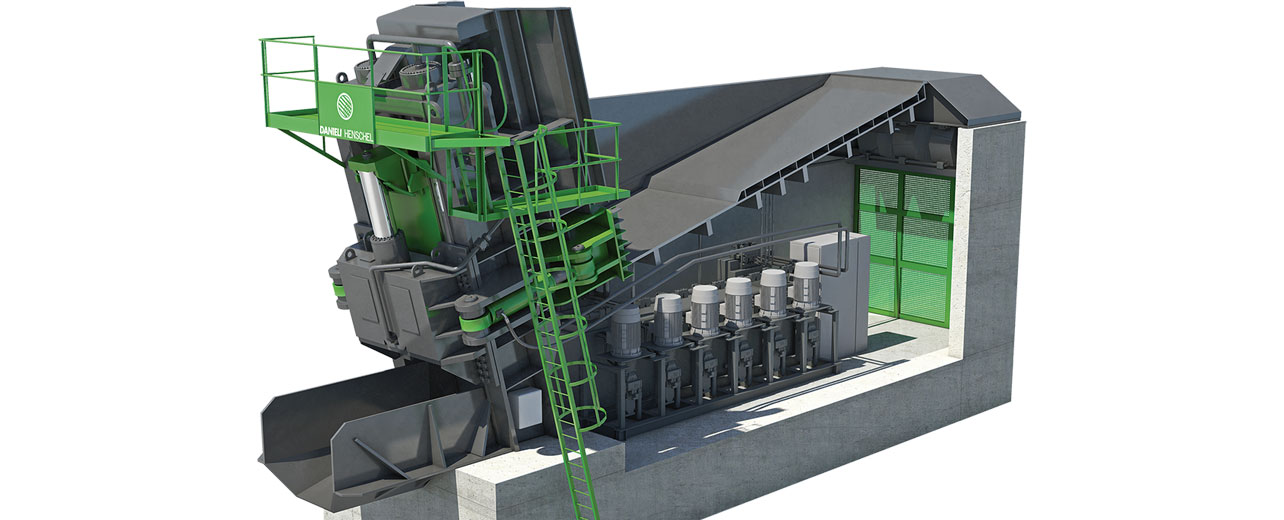

Inclined shears – CIC range

The perfect scrap shears to reduce the cost per sheared ton!

Many of our customers agree that the design of our CIC scrap shears makes them the most suitable type for the scrap metal processing and recycling industry.

For one thing, the feed chute can accept any type of scrap metal at any time, no matter what the length (up to 14 m). Because the chute is tilted, the loading height of the scrap shears is the lowest on the market.

Stationary and semi mobile machines.

Direct and continuous feeding into an open box with great storage capacity.

Not pre-processing cost of long length scrap thanks to a box with no length limitation.

Time released for the crane driver to manage the scrap yard.

Implementation surface reduced by 40 to 70% compared to other shears categories.

Reduction of the shearing ton cost.

Direct and continuous feeding into an open box with great storage capacity.

Not pre-processing cost of long length scrap thanks to a box with no length limitation.

Time released for the crane driver to manage the scrap yard.

Implementation surface reduced by 40 to 70% compared to other shears categories.

Reduction of the shearing ton cost.

Continuous automatic shearing operating cycle.

Direct and continuous loading into a vibrating inclined floor box, transporting the scrap towards the shear head.

Compression of scrap for each cycle, by means of two side flippers and a staged clamping ram.

Indexing of the shearing and reducing rams by way of magnetostrictive sensors.

Direct and continuous loading into a vibrating inclined floor box, transporting the scrap towards the shear head.

Compression of scrap for each cycle, by means of two side flippers and a staged clamping ram.

Indexing of the shearing and reducing rams by way of magnetostrictive sensors.

The CIC Range of scrap shears has the following characteristics:

– Shearing force of up to 1100 t

– Cutting width of 1400 mm

– Clamping force of up to 350 t

– Side compression force of up to 540 t

– Installed power of up to 550kW

– Output of up to 57 tph

– Shearing force of up to 1100 t

– Cutting width of 1400 mm

– Clamping force of up to 350 t

– Side compression force of up to 540 t

– Installed power of up to 550kW

– Output of up to 57 tph

Ergonomics

- Open feeding box accessible from both sides of the machine

- Better vibrating floor inclination to allow the housing of scrap of great length (up to 14m)

- Man/machine interface via touch screen display

- Machine feedback on the two-way remote control

Working life

- Overall protection of the installation: metal or concrete

- Minimum wear of the abrasion-resistant plates of the box, due to the absence of a pre-compression phase

- Generously sized guiding surfaces

- Metal protection on the clamping ram

Maintenance

- Centralised and protected maintenance

- Better accessibility thanks to implemented gangways and decks

- Automatic greasing of shear head and box

- GSM modem or telephone line for telediagnosis

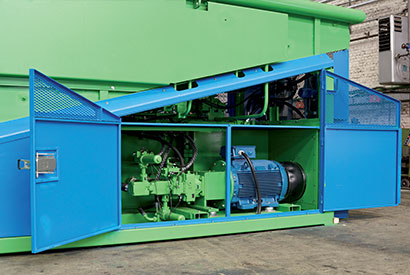

Hydraulic power unit

- Electric or diesel version compliant with latest European directives

- Hydraulic unit siuated under the feeding box, to gain important floor space

- Industrial hydraulic pumps

Safety

- In compliance with the machine directive 2006/42/EC

- Safety setting in maintenance areas

- Hydraulic hose whiplash protection

Available equipment

- Retractable cutting stop

- Hydraulic holding system on stationary blades

- Soundproofing of the hydraulic unit

- Swivelling steel plate conveyor

Applications