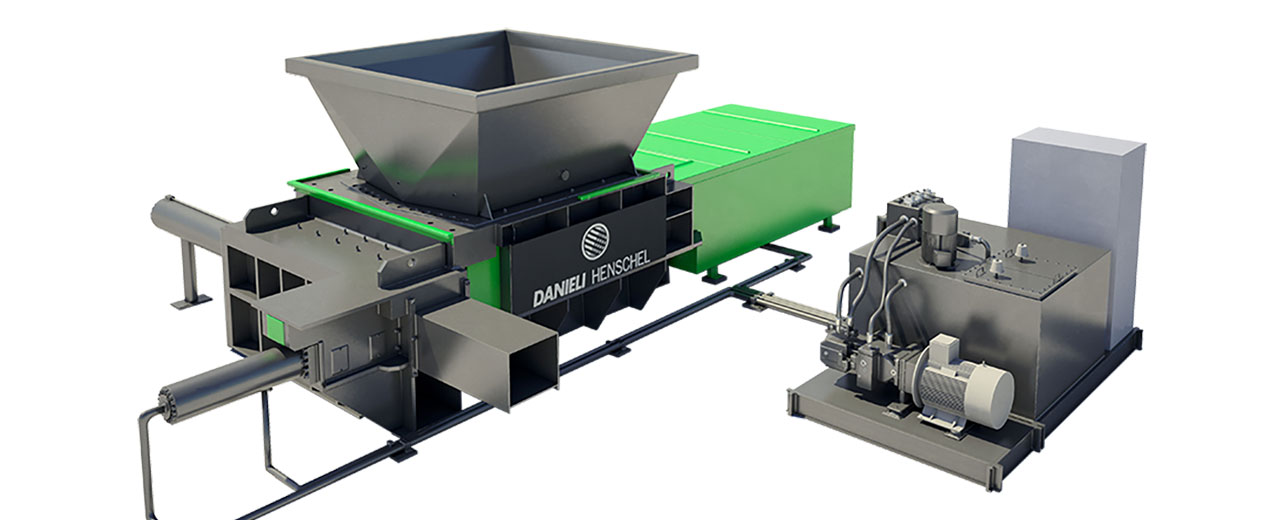

Single- or double-acting balers – PSC & PDC ranges

Our simple acting balers are particularly well designed for ease of use in the aluminum industrial sector, as well as in sorting centres making bales with UBC (Used Beverage Cans), aerosol, paint cans, etc. Their sturdy construction allows 24/24 working, optimized with the help of the Danieli Henschel monitoring interface.

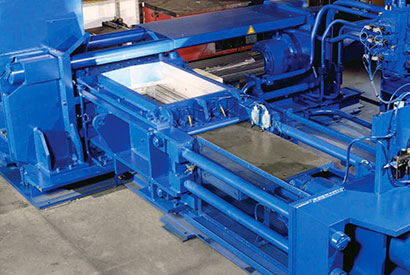

Automatic double-acting baling presses are machines used to fulfil medium and heavy production requirements. Thanks to its design of one horizontal and one perpendicular compression ram and wide loading box, these machines are highly suitable for the task of reducing relatively large pieces of scrap metal, including copper, aluminum, zinc, steel.

Very wide range of shearing ram balers.

Balers in perfect harmony with industrial surroundings.

Robust design for continuous heavy-duty operation, whatever the scrap to be baled: steel, aluminum, copper, stainless steel…

Complete turnkey supply of a series of equipment to satisfy customer requirements: automation of an industrial production line upstream and downstream from the press.

Optimization of handling, storage, and transport costs: high densification, uniform volumes (equal length).

Improved bales merging performance.

Compact design.

Adjustable number of precompressions.

Bales meter.

No specific civil work required.

Balers in perfect harmony with industrial surroundings.

Robust design for continuous heavy-duty operation, whatever the scrap to be baled: steel, aluminum, copper, stainless steel…

Complete turnkey supply of a series of equipment to satisfy customer requirements: automation of an industrial production line upstream and downstream from the press.

Optimization of handling, storage, and transport costs: high densification, uniform volumes (equal length).

Improved bales merging performance.

Compact design.

Adjustable number of precompressions.

Bales meter.

No specific civil work required.

Continuous feeding with a conveyor or a grab.

The starting of the cycle can be controlled by a weighing hopper or a level detector.

Continuous operating cycle thanks to the shearing of the first compression ram.

Manual or fully automatic operating cycle.

Production optimization and bales densification thanks to the adjustable number of precompressions.

The starting of the cycle can be controlled by a weighing hopper or a level detector.

Continuous operating cycle thanks to the shearing of the first compression ram.

Manual or fully automatic operating cycle.

Production optimization and bales densification thanks to the adjustable number of precompressions.

The PSC Range has a final compression force of up to 96 t, a bale size (output) of up to 400 x 400 mm and an installed power of up to 37kW

The PDC Range has a final compression force of up to 280 t, a bale size (output) of up to 400 x 400 mm, and an installed power of up to 90kW

The PDC Range has a final compression force of up to 280 t, a bale size (output) of up to 400 x 400 mm, and an installed power of up to 90kW

Ergonomics

- Easy implementation, suitable for the requirements of an industrial environment

- Continuous automatic operation

- Human/machine interface via touch-screen display

Working life

- Long, oversized ram guidance

- The compression chamber is sprayed with an appropriate lubricant according to the material being processed

- Appropriate grooves in the abrasion-proof wear plates according to the product being processed

Maintenance

- Centralised and protected maintenance

- Easily interchangeable wear plates

- Easy ram removal without disassembling the compression cylinders

- Automatic ram lubrication

- GSM modem or telephone line for telediagnosis

Hydraulic power unit

- Electric version compliant with latest European directives

- Industrial hydraulic pumps

- Lower energy costs through controlled use of the hydraulic system

Safety

- In compliance with the machine directive 2006/42/EC

- Limitation of bodily risks by protection and covering of risk areas (moving rams)

- Securing of maintenance areas (access hatch with cutout switch)

- Hydraulic hose whiplash protection

Available equipment

- Different systems or technologies to feed the press: conveyor, fixed hopper, bin hoist, with or without a weighing system

- Different systems or technologies to eject the bales: conveyor, ramp, non-return system, loading platform, automatic or manual bale routing

Applications