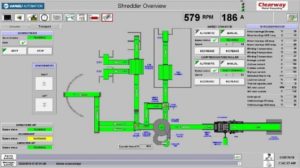

The object of the upgrade was to identify unknown existing faults in the original infrastructure which were causing plant stoppages and low machine utilization and upgrade the automation system to Industry 4.0 technology. The automation upgrade will allow the customer to operate the machine automatically and the installation of a second HMI will allow the plant downstream equipment to be operated remotely for processing materials through the downstream only. The automated plant operation will increase production and allow real time reporting of inputs and outputs to optimize operation and maintenance.

The scope of supply included site survey and installation of data logging equipment to identify the existing faults, supply of two new HMI, Hardware and Scada licenses, software development for the PLC and HMI, project management and installation and commissioning.

After successful identification of the existing problems the installation activities were divided into three phases to allow minimal stoppage of Clearway production.

First intervention Clearway pulled the new fiber optic cables and DCR personnel set the 6 new MV switches restarting the Shredder plant with the old PLC. This allowed only one day of production stoppage.

DCR personnel used this intervention to compare the old PLC software with the new PLC software and ensure full compatibility.

The Existing MV switches were left to be used with the existing CCTV system and create two separate independent networks. This was important to ensure no interference problems between the new automation signals and existing equipment.

Second intervention DCR personnel worked on PLC testing and installation in the same shift between 4p.m. and mid night avoiding any stoppage to Clearway’s plant production.

After only four days DCR were able to integrate the new equipment and start production with new PLC software producing for 90 minutes continuously.

During the installation Clearway had no production stoppage during this intervention.

Third intervention DCR process specialists worked for four days with a Danieli Automation Level 1 specialist during the production to optimize the production parameters and increase productivity. Specific menus for each type of material were installed for selection by the Clearway operators. These menus optimize the machine parameters to efficiently process different materials without the need of human input and ensure optimal production.

The new installation will allow remote connection through VPN to Danieli Automation in case of remote assistance.

Testimony from Mr Vincent Boyle, Managing Director of Clearway Recycling:

“Clearway personnel are pleased with recent hardware and software upgrade for our 400ohp shredder plant in Belfast. The plant was originally supplied by Lynxs prior to their acquisition by Danieli. The whole procedure was very professional. In the first instance Danieli held discussions with Clearway to agree the scope of supply and how this would meet all our expectations. A contract was agreed and Danieli engineers spent a few days on site gathering information and monitoring the existing plant before work on the upgrade commenced. Clearway wanted to minimise plant downtime during the upgrade so Danieli organised their work on two separate phases 3 weeks apart. In the first phase (5 days) they replaced internal optical fibre network and this work was carried out, outside of our normal working hours. In the second phase (12 days) much of the work was again carried out, outside of our normal working hours. When testing and optimising the new software for the control system the disruption to production was much less that we had expected, which was important for our production.

The Danieli engineers which were involved in the project on site and off site communicated very well with all the Clearway personnel that they were dealing with and they quickly established good working relationships and understanding of what we required at all stages of the project from the original specification, pre-site preparation, on-site implementation and final handover.

We are now considering a similar upgrade for another DCR shredder plant in our Dublin operation.”