– Plug & Shred Solution

Smart Power Technology for Recycling Process.

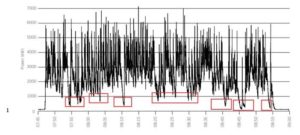

Modern industrial activity requires flexibility and efficiency to ensure responsiveness to market demand, but that is not the case for the power drive systems traditionally applied to scrap shredders. Such systems – slip ring motor with Liquid Resistance Starter (LRS); direct starter at full or reduced voltage; hydraulic transfer coupling; and combined DC solution with motor and converter – are not optimizable according to scrap quality and density, operating conditions and wear parts, resulting in a static process with low productivity, high maintenance/production costs, and high energy consumption. Danieli Automation and Danieli Centro Recycling have jointly designed and supplied Smart Power Technology with an innovative control strategy for energy saving, improved productivity, better use of wear components and reduced impact on the MV distribution network. The graph in figure 1 represents the total power demanded by a 4,000 hp motor during normal production with traditional LRS. Analyzing the power requirements,we observe the following effects:

— Many intervals at no load or reduced load (red boxes).

— Average power is low compared to the motor nominal power, with a real motor-service factor limited to 65%.

— Repetitive, uncontrolled power peaks above the motor maximum overload.

— Slow response of the LRS to tune and adapt the rotor resistance to load conditions. — When using the LRS, there is considerable energy wasted in the heat, quantifiable up to 10%

Impact on the process and network of a conventional or LRS solution.

Impact on the process and network of a conventional or LRS solution.

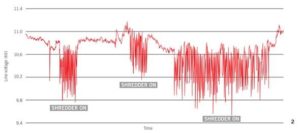

Power Quality Measurement of the LRS solution reveals other effects on the distribution network, including: — The line RMS value in load condition is characterized by rapid transients (swells and dips), due to rapid shredder load variation. The voltage fluctuation influences other motors/ loads too, with additional transients in network current and impact on power quality in the upstream distribution system. (Figure 2)

The Plug&Shred solution

The Plug&Shred solution

A MV/LV inverter with dedicated firmware, in combination with an adaptive control strategy, ensures better productivity without network disturbances. In addition, the Plug&Shred solution makes it simple to convert an existing, fixed-speed Direct On-Line 3-Phase Asynchronous Motor (with squirrel cage or wound rotor) to a state-of-the-art Variable Speed Drive system, without requiring cumber some sinusoidal filters to preserve motor insulation integrity. Among the features: — No motor derating for voltage insulation;

— No motor derating for power and thermal performances;

— No modification required to adapt the motor to the drive; — Easily applicable to existing motors without the need for an expensive output filter;

— Eliminates the need for special VFD rated cables;

— No Neutral Shift; and,

— Motors do not require surge protection.

The Plug&Shred solution makes the conventional solutions (LRS, Hydraulic Transfer Coupling, DOL, DC system) obsolete in terms of technology and performance. In comparison with a combined DC system, motor and thyristor rectifier, the Plug&Shred solution also eliminates the typical problems of an obsolete DC drive solution:

-Low efficiency

-High cost of DC motor maintenance (brushes and collector)

-Low and limited overload capability, network disturbances (harmonics and low power factor)

-Sensitive and inadequate solution for weak network, etc.

Advantages and Benefits of Plug&Shred variable-speed drive for scrap shredding

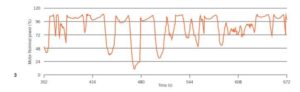

1. Limited Power peak demands A variable-speed drive for a shredder motor limits the power peaks and provides instant control of the power requested during production. The graph in figure 3 (10-msec sample) indicates power control for a shredder driven by 3,000-hp motor. During production, the motor never exceeds 110% of nominal power, independent of operational and overload conditions. Drive correction is immediate, responding in a few milliseconds (compared to several seconds typical of a LRS response.) Power limit can be set in the HMI, according to the energy supply contract and contractual power limit available at different time slots, avoiding power excesses penalty.

2. Dynamic motor torque utilization. Motor utilization will be thermally optimized, using variable torque limits function of the windings temperature.

3. Motor control accuracy and response time. Drive controls and manages motor torque in real-time, with high accuracy and immediate response, avoiding mechanical stress for the cardan shaft in case of overload.

4. Energy savings. Variable-speed drive energy savings average 8-10%, or up to 15-20% depending on operational decisions.

5. Reduced consumption of the wear parts. Adapting the motor speed, power and torque limits to the different scrap density, the wear of the consumable components can be reduced up to 10-15%.

6. Production enhancement. The “Adaptive Auto Pilot” in combination with an inverter manages the motor in overload condition, for higher average power.

7. Reduced electrical maintenance. Using an inverter reduces maintenance requirements for electrodes, electrolytic solution, and mechanical alignment, and there is no LRS cooling system.

8. Reduced impact on the network. Network disturbances due to the shredder will be corrected thanks to real-time power control, smoothing the effect of sudden load variations, sources of swells and voltage dips, hence flicker disturbances.

9. Higher input power factor. A MV/ LV drive ensures a higher line-power factor in the full range of speed, not requiring a power factor compensator.

10. Input harmonic suppression. Plug&Shred drive meets harmonic regulator’s guidelines IEEE-519, without the use of harmonic filters.

PLUG & SHRED DRIVE SECTION SOLUTION

– LV drive up to 690V and up to 3000kW

– MV drive up to 11kV and up to 10MW

-Air or water cooled

-Ultra-low harmonic solution

-High overload capability

-Regenerative

-Power configuration and firmware for weak network