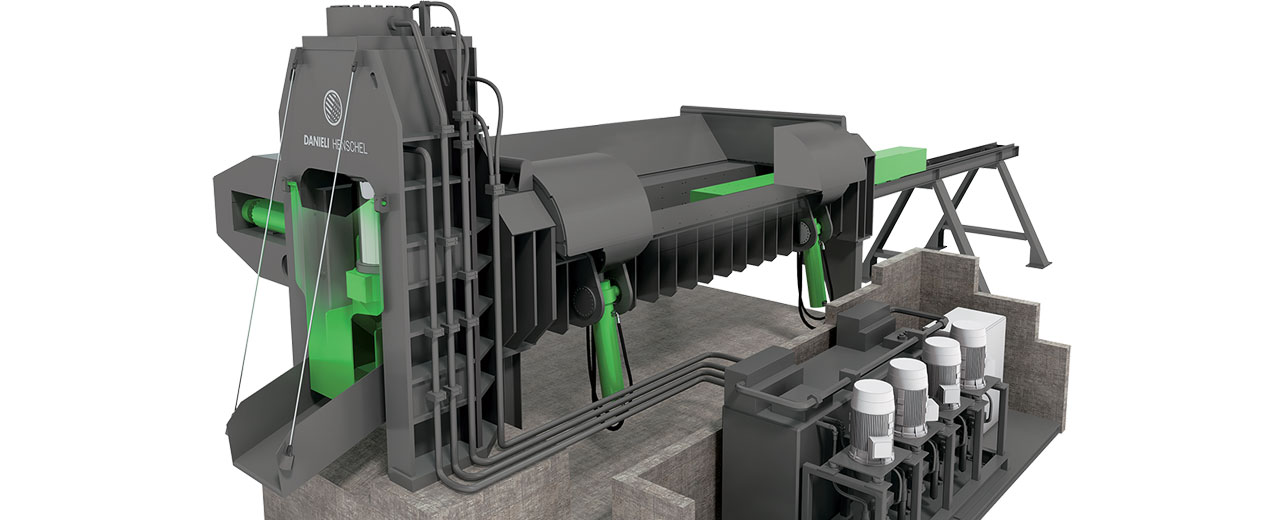

Scrap shears with side compression – CIB range

The heavyweight champions: Danieli Henschel scrap shears with lateral pre-compression box come in six box/reducer combinations: two- or three-level box, one- or two-part lid, parallel- or variable-entry-angle reducer!

We are one of the only makers of CIB-type hydraulic scrap shears able to provide a lateral pre-compression box that can travel parallel to the pusher ram or at a variable entry angle. This versatility is a definite asset when the operator comes up against a crush-resistant piece of scrap metal. By approaching the material off-axis, the reducer will compress the material on a smaller surface, increasing the pressure on the piece of scrap metal. The CIB range is ideal for processing heavy and bulky scrap metal, where high densification and productivity are required.

High cutting capacity to cut heavy scrap metal.

Precise cutting length.

Optional cupola system.

Three possible box / reducer combinations giving optimum compression for any type of scrap:

– Two- or three-stage box

– Standard or extended lid, one-piece or two-piece

– Parallel or variable entry angle reducer

Man/machine dialogue.

Direct loading or with skip.

Manually or automatically controlled pre-compression between a flattening lid and a side reducer, both with over-stroke function.

Indexing of the shearing and reducing rams by way of magnetostrictive sensors.

Laser positioning of the ram.

The CIB Range has the following characteristics

– Shearing force of up to 1600 t

– Cutting width of 1500 mm

– Pusher force of 180 t

– Lid force of 600 t

– Lateral reducer force of 600 t

– Installed power of 720kW

– Output of sheared scrap, up to 98tph

- Easy installation, made to suit customer requirements

- Machine feedback via control cab or bidirectional remote control

- Human/machine interface via touch screen

- Shearing cycle to suit your requirements

- Lid and lateral reducer over-stroke

- Generously sized guide surfaces

- Anti-abrasion wear plates

- Improved accessibility

- Optimised blade replacement phase

- Simple shearing ram adjustment by excentrics from outside the shear

- Grouped weekly lubrication points

- GSM modem or telephone line for telediagnosis

- Electric version compliant with the latest European directives

- Containerisable hydraulic unit

- Industrial hydraulic pumps

- Compliant with machine directive 2006/42/EC

- Maintenance area lockout

- Hydraulic hose whiplash protection

- Cupola system for more compact waste at the output

- Extra-lid and Power-S lateral reducer

- Hydraulic blade holding

- Automatic lubrication of shearing head and charging box

- Fully equipped and air conditioned control cab

- Scrap cleaning system downstream from the shear using a vibrating table and conveyors