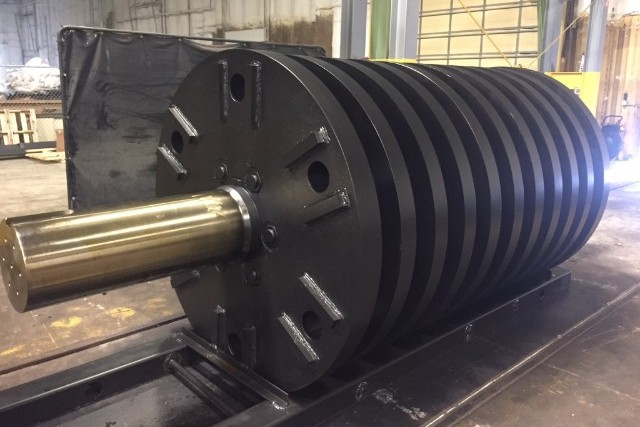

Custom designed rotors

Danieli Centro Recycling offers a complete line of plate rotor designs, from the industry standard of high hardness alloy to our new extended-life Carbon Series that can be custom designed to each application. Danieli Spider Rotors are proven to be the longest lasting rotors in the North American industry, providing higher production yields and increased profits for our customers. Danieli offers four and six arm assemblies for both helmet and T-capped spiders. The new Carbon Series Spider Rotor assembly utilizes spider tip designs that significantly improve life and performance.

Rotors available from 36” -130” shredders.

Danieli Centro Recycling engineers analyze each customer’s current operation, from the infeed process through take-away and design a comprehensive package specific to each application. Every Danieli Centro Recycling rotor is precision manufactured to integrate seamlessly with its corresponding wear part components to provide each customer with the most efficient and cost effective production solution.

Danieli Centro Recycling’ most recent advancement is the introduction of its new Carbon Series line of products. An industry breakthrough resulting from a multi-year development program, Carbon Series products incorporate a unique carbon alloy formulation and specialized manufacturing process.

Our Carbon Series rotors, hammers and spider caps have revolutionized the life expectancy of metal shredding wear parts while simultaneously increasing total material throughput and a higher quality shred.